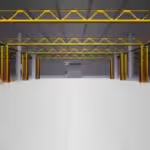

Modern construction advancements prefer PEB Structure for their efficiency, cost-effectiveness, and sustainability. Workers assemble prefabricated elements on-site to create the structures, which have been designed beforehand. In industrial, commercial, and agricultural sectors, PEB structures can be used. Understanding PEB structural components is crucial to grasp design and construction intricacies. We’ll first examine the main elements of a PEB structure.

What is PEB Structure?

A pre-engineered building (PEB) is a system of structures that uses standardized factory-made components. Fabricating components in a workshop and assembling them on-site using bolts reduces construction time and costs significantly.

PEB structures are versatile, ideal for various applications like warehouses, factories, commercial buildings, leisure places, and residences.

The Components of PEB Structure:

1. Primary Frame Component: The main lobby greets the visitors with the super frame. It consists of the following elements:

A. Columns:

- Purpose: Vertical members that support loads from the lower floors passed to the ground through the foundation.

- Types: The steel section type, I-shape or H-shape, besides diameter, determines its ability to handle axial load and bending.

B. Rafters:

- Purpose: I-joists are or those sloped beams which span between columns, supporting the roof load.

- Types: I-sections or H-sections provide effective roof structural support.

C. Girders and Trusses:

- Purpose: Make sure that the structures with the large span get additional support members.

- Types: Girders are horizontal beams, trusses are triangular frames with high force-to-weight ratios, allowing large open spans without interior columns.

2. Secondary Structural Component: These components support the primary frame and enhance the overall stability of PEB Structure:

A. Purlins:

- Purpose: The washers support the roof deck by spanning walls and transferring weight to rafters.

- Types: These usually are a Z-shaped section or C-shaped channel load-bearing steel elements, which convey the loads.

B. Girts:

- Purpose: Horizontal members at walls transfer the load to columns, serving as supports.

- Types: Z or C shapes stabilize wall panel openings like purlins do.

C. Eave Struts:

- Purpose: Transverse contiguous pieces along the top of the wall, underneath the roof slopes. The apex is known as the eaves.

- Types: The roof and walls, shaped as C or Z, support their loads.

3. Roofing and Cladding: The elements protect and enhance the PEB structure’s appearance:

A. Roof Panels:

- Purpose: The first part of our scheme plays the role of the outermost layer of the roof while it is a shield defending the building from weather.

- Types: Constructed from corrugated metal sheets with protective coatings, a material is typically used for such structures to improve tolerability.

B. Wall Panels:

- Purpose: While serving as the outer skin of the building and as a structural feature, it also is an appealing view.

- Types: Veneers come in various patterns and materials like metal sheets, sandwich panels, and fiber cement boards.

4. Other Accessories: PEB constructions include various parts and additional accessories for enhanced functionality and convenience:

A. Doors and Windows:

- Purpose: The entrance and ventilation are vital for the building’s functionality.

- Types: The building’s spatial layout or the whole usage cycle could be the basis for modularization.

B. Ventilators:

- Purpose: Spin the inside air to minimize the effect of heat clouds

- Types: Users should employ ridge vents and roof-side exhaust fans.

C. Insulation:

- Purpose: You can increase your thermal proficiency and have your bill paid more easily.

- Types: Enclosures benefit from fiberglass or reflective technology and closed-cell foam for insulation.

D. Gutters and Downspouts:

- Purpose: To prevent the building’s foundation from water damage, design a rainwater management system.

- Types: Made of metal with PVC and available in a variety of designs to fit the drainage requirements.

How G Sky Eagle Enhances PEB Components:

G Skyeagle Infra leads the PEB market globally with customized design, installation, and steel fabrication services. G Skyeagle Infra excels in optimizing PEB structures with expertise in manufacturing, construction, and architecture, emphasizing efficiency, durability, and cost-effectiveness.

A. Customized Design Solutions:

G Skyeagle Infra designs personalized options frame by frame, tailored to client’s unique demands, plot specifics, and budgets. By combining software, engineering techniques, and design principles, this flying device reduces material use and construction time significantly.

B. High-Quality Materials and Fabrication:

G Skyeagle Infra sources top-quality steel and building materials from trusted suppliers for durable, corrosion-resistant PEB steel installations. With robotized facilities and highly qualified craftsmen, we deliver armature components promptly.

C. Value-Added Services and Support:

G Skyeagle Infra provides project management, logistics coordination, and on-site supervision for timely project completion. Skilled engineers support the project from design to commissioning.

D. Sustainable Solutions:

G Skyeagle Infra focuses on eco-friendly design concepts for construction, prioritizing carbon footprint and energy efficiency. G Skyeagle Infra helps clients achieve sustainability goals through eco-design, cost-efficient materials, and renewable energy for maximizing PEB investment.

In summary, the fabric structure components are crucial for durable, functional, and cost-effective architecture. Customers benefit from alliance solutions with leading producers like G Skyeagle Infra, offering tailored PEB structures.